EN 13704:2018

Quantitative suspension test for the evaluation of sporicidal activity of chemical disinfectants used in food, industrial, domestic and institutional areas.

EN 13704:2018 is a phase 2 step 1 suspension test for disinfectants intended for use in the food, industrial, domestic and institutional areas. The test evaluates the efficacy of the product against bacterial and fungal spores.

The 2018 version of the test replaces the 2002 version and include the following major changes:

- The new version has a modification in the spore preparation procedures which includes spore maturation time.

- The minimum and maximum conditions for contact time and temperature have been added along with the test procedures for dirty conditions.

- The results obtained with the previous version are not valid.

- The recent version includes spore suspension susceptibility controls. Bacillus subtilis and Bacillus cereus spores are verified using two concentration levels of glutaraldehyde and peracetic acid solutions.

- With Bacillus subtilis without interfering substance:

- 3.0% (v/v) – 30 min: Glutaraldehyde solution should achieve a lg reduction of < 3 lg

- 10.0% (v/v) – 30 min: Glutaraldehyde solution should achieve a lg reduction of ≥ 3 lg

- 0.001% (v/v) – 30 min: Peracetic acid solution should achieve a lg reduction of < 3 lg

- 0.05% (v/v) – 30 min: Peracetic acid solution should achieve a lg reduction of ≥ 3 lg

- With Bacillus cereus without interfering substance:

- 0.5% (v/v) – 15 min: Glutaraldehyde solution should achieve a lg reduction of < 3 lg

- 3.0% (v/v) – 15 min: Glutaraldehyde solution should achieve a lg reduction of ≥ 3 lg

- 0.05% (v/v) – 30 min: Peracetic acid solution should achieve a lg reduction of < 3 lg

- 0.50% (v/v) – 30 min: Peracetic acid solution should achieve a lg reduction of ≥ 3 lg

According to EN 14885:2015 for the application of European Standards for chemical disinfectants, clause 8.1 states that manufacturers shall test their products with the latest version of a norm within 18 months after publication of the new version. As there are technical changes in the new version of EN 13704, manufacturers are required to re-test all their products according to this method before 30 July 2020 (within 18 months). Results tested according to EN 13704:2002 will not be valid after 31 January 2019. This is based on Viroxy’s interpretation of the European standards and clauses.

Test Conditions

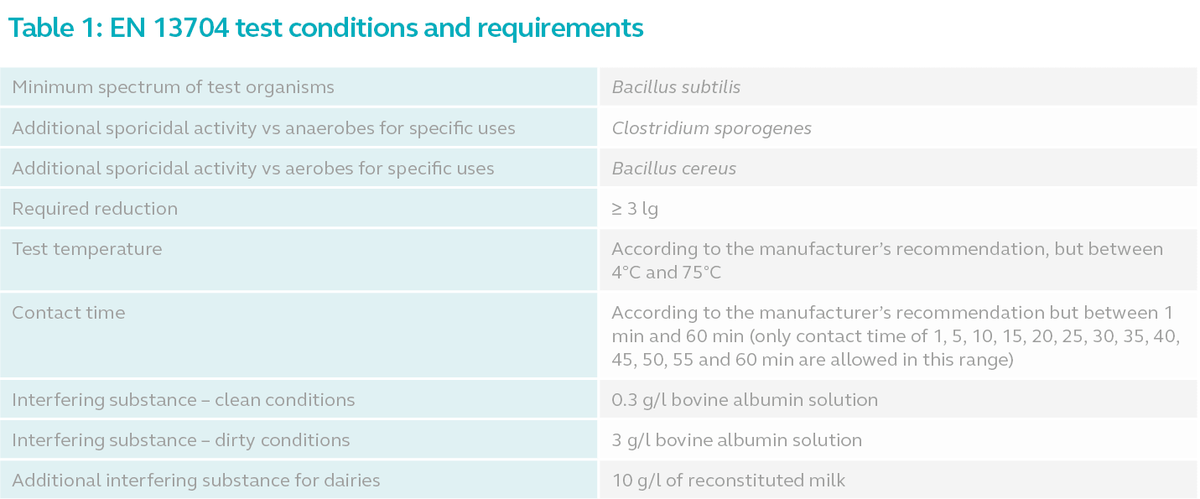

The standard refers to the parameters to be observed when testing products intended for surface disinfection. This includes the test microorganism, test temperature, contact time and interfering substance.

- Test microorganism refers to the mandatory list of microbes that must be used in the test to determine the antimicrobial activity of the product. The mandatory microorganisms are assumed to represent all microbes in its group.

- Test temperature refers to the temperature in which the test must be conducted. The general assumption is that disinfectants are less effective in low temperatures compared to higher temperatures.

- Contact time refers to the minimum duration a product must remain in contact with the microbes for the product to be effective.

- Interfering substance refers to substance used in the test to simulate the possible contaminants that co-occur with microbes in the actual environment.

Refer to the table below for the minimum and additional test conditions.

Test Method

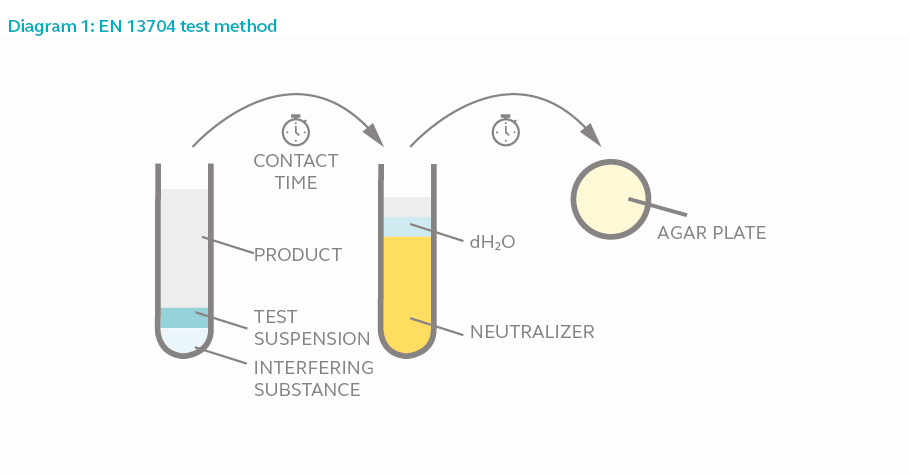

In a phase 2 step 1 suspension test, 8 parts of the test product is added to 1-part test microorganism and 1-part interfering substance. The mixture is allowed to interact for the duration of the contact time. One part of the mixture is added to 8 parts of neutralizer and 1-part water for 5 minutes to halt antimicrobial activity. The final mixture is then acquired and incubated for 3 days to allow surviving spores (if any) to proliferate. The colony is counted and compared against the original culture size.

Log Reduction

Log reduction refers to the extent to which a product is capable of reducing the number of microbes. For example, 4-log reduction means the number of microorganisms on a surface has been reduced by 10 000 times. A product that is 99.9% effective against a certain microbe is said to have achieved 3-log reduction against that microbe.

For a product to pass EN 13704, it must be able to achieve 3-log reduction against the respective test microorganisms listed in Table 1. In other words, the product must be able to kill 99.9% bacterial spores while meeting all the other requirements of the European standard.