Material Compatibility

Ensuring the integrity and performance of dental equipment and materials

In the dental industry, material compatibility is crucial to ensure the effectiveness, safety, and longevity of dental equipment and materials. It refers to the ability of different dental materials to retain its quality, aesthetic and shelf life based on their chemicals resistance, heat resistance, tear strength resistance, tensile bond strength resistance or elasticity.

The concept of material compatibility impacts various aspects of dental practice. For instance, when choosing materials for dental prosthetics like crowns, bridges, or dentures, dentists must ensure that these materials can withstand the forces of chewing and grinding while maintaining their integrity over time.

They are tested worldwide to validate the compatibility with various chemicals and mechanical forces. Many regulatory bodies, for example Medical Devices Regulation in the Europe, requires dental equipment to be tested before they are allowed in the market.

International Organization for Standardization

Material compatibility testing according to EN ISO 21530 is mandatory under MDR to ensure your disinfectant is dental equipment friendly.

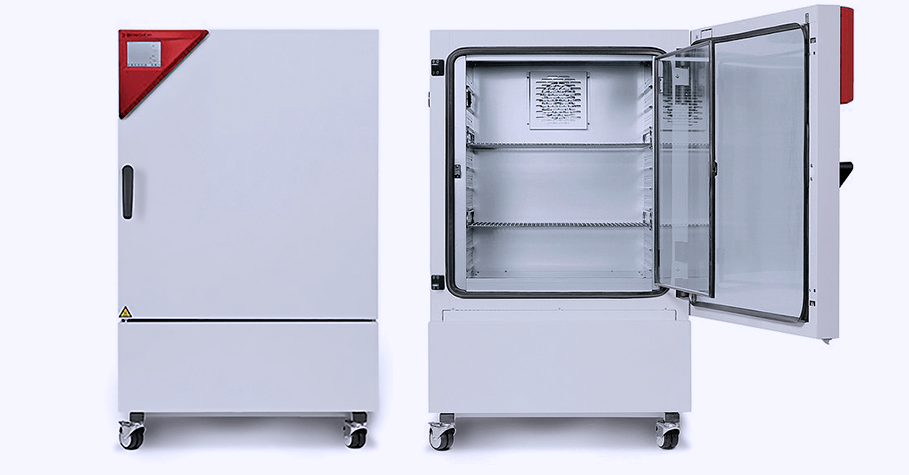

Climate chamber to control temperature and humidity during material compatibility testing

Although R&D experts have a general idea how a substance reacts with others, the extent to which the final formula will damage a surface material can only be determined through material compatibility testing.

The Medical Device Regulations in Europe require manufacturers to test disinfectants for dental equipment and surfaces according to EN ISO 21530 before they are released in the EU market due to the potency of the active ingredients often used in the development of disinfectants. Most antimicrobial agents such as alcohol, chlorine dioxide and hydrogen peroxide can damage certain (not to mention, expensive) surfaces instantaneously or over a period of time.

However, there is a safe threshold for every product containing these active ingredients, making it suitable for the intended use. Material compatibility testing identifies these thresholds to prevent dental service providers from facing financial losses due to premature instrument and surface degradation.

The concentration and exposure time of sample is pre-determined to form the basis of compatibility test. One important factor to remember at this stage is the intended use of the disinfectant. This simply means that the test must consider the materials that the disinfectant is expected to come in contact with during the course of its use.

At Viroxy, we help manufacturers determine the compatibility of their products against a wide range of surfaces and materials. We are capable of testing disinfectants on genuine leather, stainless steel, polyethylene, latex and various other materials.

Our clients typically request for these 2 tests:

Material compatibility soak test

Materials commonly used in this test include stainless steel, aluminium and copper. The material is visually inspected, weighed and photographed to record its condition before exposure to sample. Next, the test material is immersed in the sample either completely or partially for a predetermined period of time over several cycles to determine how much exposure the material can withstand without damage. The test material is then removed, inspected visually, weighed and photographed again to record the changes. The average time required to complete a material compatibility soak test is 14 days.

Contact test

Contact test is usually performed to test the compatibility of a disinfectant with the surfaces it is meant to be applied to. Common materials used in this test include artificial leather, polymethyl methacrylate and latex. As in material compatibility soak test, the test material is first visually inspected and the condition recorded. Next, a cotton ball soaked with sample solution is placed on the test material to cover at least 50% of the surface. The cotton ball is replaced with a fresh soak every 24 hours for 14 days. The test material is then inspected again for changes such as discolouration and surface bubbles.

Common factors that contribute to material incompatibility

There are two common factors that contribute to material incompatibility:

- The level of acid or alkali content in the test sample – extreme acidity or alkalinity can damage most substances.

- The presence of oxidizing agents – oxidizing agents such as hydrogen peroxide and chlorine can corrode certain substances with prolonged exposure.

Material compatibility testing is necessary for every disinfectant intended for use in the dental industry. Mainly because the industry uses several equipment made from sensitive materials such as dental impressions, dental chairs and burs. Depending on the type of material used to manufacture the equipment, they may deteriorate rapidly if the wrong type of disinfectant is used or proper care is not administered.

Material compatibility testing helps manufacturers identify and declare the types of materials their disinfectant is compatible with so that users can determine what’s best for their facility.

At Viroxy, you can request to test your disinfectant on a specific material and we will test them according to EN ISO 21530 standards.

International Organization for Standardization

EN ISO 21563 Hydrocolloid impression materials

EN ISO 21563 details the composition, physical properties, and performance characteristics that these materials must meet to ensure their reliability and consistency in dental practice. Hydrocolloid impression materials are crucial for creating accurate molds of dental structures, which are essential for fabricating precise dental prosthetics and restorations. Compliance with EN ISO 21563 helps dental professionals achieve consistent results in impression-taking, contributing to the quality and effectiveness of dental treatments provided to patients.